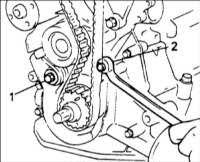

1 - a bolt, 20-27 Н•м;

1 - a bolt, 20-27 Н•м; 2 - a spring of the mechanism of a tension;

3 - a roller of a tension of a gear belt;

4 - the free party of a gear belt;

5 - a bolt, 80-100 Н•м;

6 - a camshaft pulley;

7 - an adjusting pin; 8 - the party of a tension of a gear belt;

9 - an adjusting label (index) on a forward cover;

10 - an adjusting label on a pulley of a cranked shaft;

11 - a pulley of a cranked shaft.

Removal

PERFORMANCE ORDER

1. Los a bolt of fastening of a pulley of the water pump.

2. Los a bolt of fastening of the generator.

3. Remove a pulley of the water pump and a belt.

4. Remove a pulley of a cranked shaft.

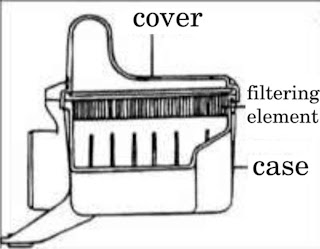

5. Remove a casing of a gear belt.

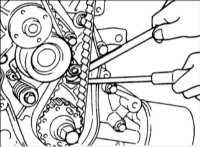

6. Move a roller of a tension of a gear belt to the water pump and temporarily fix it in this position.

6. Move a roller of a tension of a gear belt to the water pump and temporarily fix it in this position.7. Turn out a bolt of fastening of a pulley of a camshaft.

8. Remove a camshaft pulley.

9. Remove a gear belt.

The prevention

The prevention Note a direction of rotation of a gear belt for its repeated installation in initial position.

10. Turn out a bolt of fastening of a pulley of a cranked shaft. Remove a pulley of a cranked shaft and the plug.

11. Remove a roller of the mechanism of a tension of a gear belt.

Check

The prevention

Strongly do not bend a gear belt and do not change a direction of its rotation. Do not allow oil and lubricant to contact with a gear belt as it will lead to its destruction.

PERFORMANCE ORDER

1. Check up a gear belt on absence of damages, deterioration, stratification, cracks on teeths and in the basis of teeths, and also on defects at end faces and a belt underside.

2. In the presence of following defects replace a gear belt

Pulleys and roller of the mechanism of a tension of a gear belt

Pulleys and roller of the mechanism of a tension of a gear belt PERFORMANCE ORDER

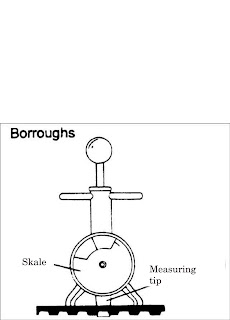

1. Check up pulleys of distributive and cranked shaft, a roller of the mechanism of a tension and a single pulley on absence of non-uniform deterioration, cracks and damages.

2. Check up ease and smoothness of rotation of a roller of the mechanism of a tension and a single pulley, and also absence of extraneous noise at rotation.

Installation of the mechanism of a tension of a gear belt

PERFORMANCE ORDER

1. Temporarily fix the mechanism of a tension of a gear belt in the taken away position as it is possible more close to the water pump.

2. After installation of the mechanism of a tension adjusting labels on pulleys of distributive and cranked shaft should be combined with indexes.

2. After installation of the mechanism of a tension adjusting labels on pulleys of distributive and cranked shaft should be combined with indexes.Turn a cranked shaft of the engine so that the piston of the first cylinder was established in ВМТ in a compression step.

PERFORMANCE ORDER

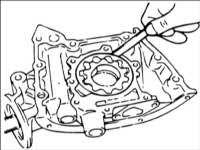

The prevention

Be convinced, that the plug is established correctly, thus the facet should be from the forward party of the engine.

1. At installation of a pulley of a camshaft the adjusting pin should enter into a pulley aperture.

2. Establish a gear belt so that to exclude its sagging from a tension.